| Sign In | Join Free | My china-telecommunications.com |

|

| Sign In | Join Free | My china-telecommunications.com |

|

| Categories | Extrusion Blow Molding Machine |

|---|---|

| Brand Name: | MEPER |

| Model Number: | MP70D |

| Certification: | CE/ISO9001:2008 |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | Price negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 sets per month |

| Delivery Time: | 25-35 work days |

| Packaging Details: | Standard export package, wooden pallet(standard) wooden case(optional) |

| Bottle: | 1L Chemical Pesticide Bottle |

| Applicable Material: | HDPE LDPE PP PETG PVC PC PA EVOH EPET |

| Layer: | 4 layer |

| Head: | 2-3 heads |

| Product: | chemical bottle |

| Machine type: | Tie Bar type -D type |

| Company Info. |

| Ningbo Qiming Machinery Manufacturing Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

4 Layer Double Station Extrusion Blow Molding Machine For 1L Chemical Pesticide Bottle

Introduction:

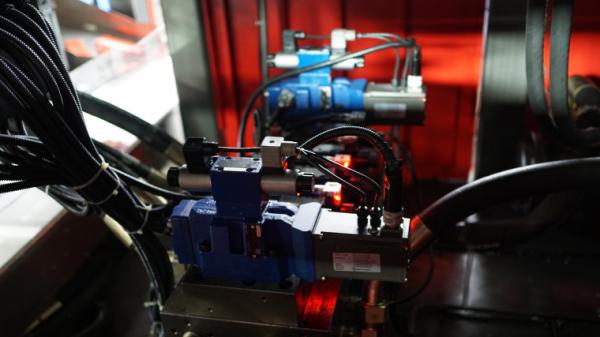

MP70D is specifically designed for making bottles from 50ml up to maximum 5L. It is hydraulic driven with accrate eletrical control system. MP70D has double stations to increase the production efficiency. Also, it has variety of choice of die heads. With more than 10 years of success in the market, MP70D is updated to be one of the most reliable and popular model in the world.

Advantages:

EXTRUSION DIE HEAD: HIGHLY EXPERIENCED MULTI-CAVITY AND MULTI-LAYER TECHNOLOGY

Adopting with latest die head design, MEPER focuses on providing high quality and high precision self-manufactured extrusion die heads for customers.

| MP70D Double station blow molder with horizontal linear mould shuttle | ||||

| Length: | 3600mm |

| ||

| Width: | 2200mm | |||

| Height | 2360mm | |||

| Key Data | MP70D | |||

| mm | ||||

| Linear mould stroke | A | 450 | ||

| Mould Width | B | 430 | ||

| Mould Length | C | 350 | ||

| Mould Thickness | D | 190 | ||

| Opening Stroke | E | 290 | ||

| Platen daylight | D+E | 480 | ||

| Clamping Force | 75kN | |||

| Dry Cycle | 7 sec. | |||

| Centre Distance | 2x2 fold | 160 | ||

| 2x3 fold | 120 | |||

| 2x4 fold | 100 | |||

| 2x6 fold | 60 | |||

| Extruder | φ70 | φ75 | φ80 | |

| Screw Speed | r/min | 0~65 | 0~65 | 0~65 |

| Screw Diameter | mm | 70 | 75 | 80 |

| Screw L/D Ratio | L/D | 24 | 24 | 24 |

| Energy Requirements | ||||

| Extruder Inverter Power | kW | 18.5 | 22 | 30 |

| Extruder Moter Power | kW | 18.5 | 22 | 30 |

| Srew Heating Power | kW | 12.7 | 14.4 | 15.85 |

| Fan Power | kW | 0.14X2 | 0.14X2 | 0.14X2 |

| Oil pump Motor Power | kW | 9.5 | 9.5 | 9.5 |

| Total Power of Machine | kW | 49.14 | 54.34 | 63.79 |

| Air Requirement approx | m3/min | 1.2 | 1.2 | 1.2 |

| Air Working Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Cooling Requirements | ||||

| Consumption Cooling Water | L/min | 40 | 40 | 40 |

safety door device

The main function of Safety door is that preventing operator from entering into machine and putting hand into mould when mould platen is running.

Safety door installs obstructing shaft, limited sensor, stroke switch, which prevent people from entering into machine. limited sensor belongs to one kind of electric safe. When you close the door, it will contact sensor, then the clamping system works; when door is open, sensor doesn’t work, electric diagram is in a safe situation. stroke switch is also one kind of electric safe, when stroke switch is in a safe situation, if operator enter into door, then machine will give a alarm.

|